Tutorial 2

We have familiarized ourselves with the basics of resistors and its application. In this article, we will learn about different types of Resistors and basic guidelines for choosing resistors based on different applications.

Before going into the detail about different types of resistors, let us revisit and understand again what is Electric Resistance.

Definition of Resistance

The property of materials that opposes the flow of electric current through it is called resistance, in simple words resistance is an inherent property of materials that opposes the flow of current. We have covered about how resistors works in our previous tutorial.

Different Types of Resistors

We know resistors are extensively used in different electronic circuits. Different types of resistors possess different characteristics and properties. Three major characteristics of resistance are ohms, power rating, and tolerance. The resistance of a resistor is measured in Ohms and its power rating is measured in Watt and the deviation from the manufactured value is known as tolerance.

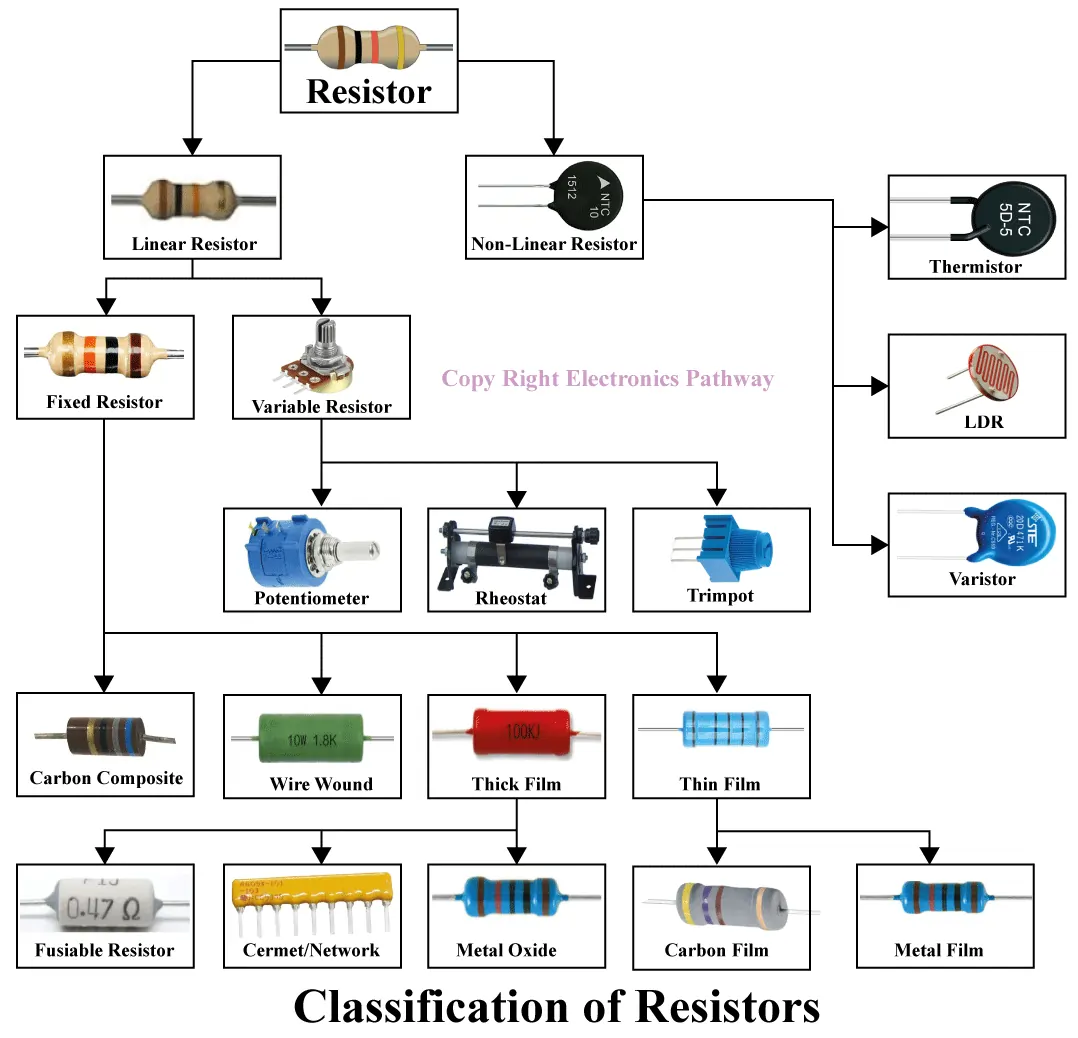

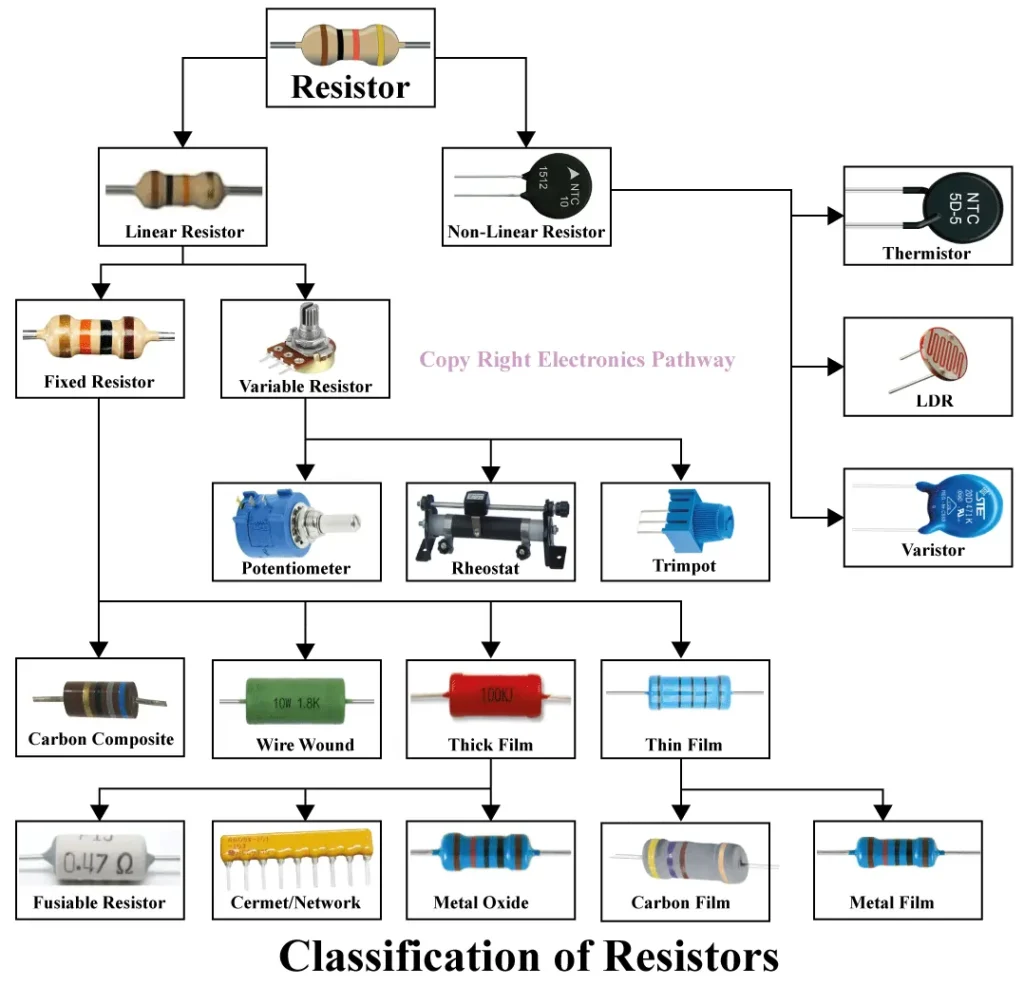

Here, we will see in detail about different types of resistors. Based on working principle, material composition, and application use, we can divide resistors into two major types.

- Linear Resistors

- Non-Linear Resistors

Linear Resistors

There are different types of resistors, Linear Resistors are such types of resistors whose resistance does not vary no matter how much voltage or current is applied. More formally we can define linear resistor as a type of resistor where the relationship between voltage and current obeys Ohms Law.

In simple words, in linear resistors, if we increase the voltage, the current increases in the same proportion, however, the resistor resistance value remains the same.

Furthermore, these are different types of resistors however, in broad case there are two major types of linear Resistors :

- Fixed Resistors

- Variable Resistors

Fixed Resistors

Fixed resistors are the most widely used resistors among different types of resistors in electronic devices. Fixed resistors are those whose resistance value does not change with the change in voltage or current. In simple words, its resistance remains constant and we cannot change it.

However, we find some deviation in the resistance of fixed resister with the temperature change. The symbol of a fixed resistor is shown below.

These fixed resistors are also further classified into different types based on the manufacturing process and the material used.

- Carbon Composition resistor

- Wire wound resistor

- Thick Film Resistor

- Thin Film Resistors

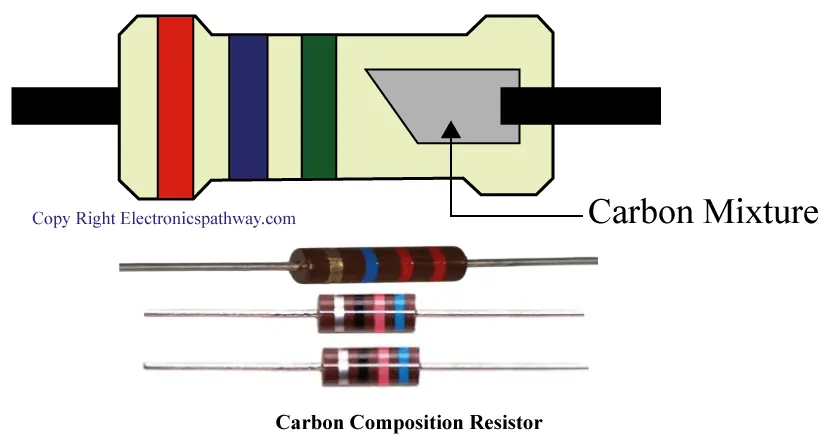

Carbon Composition Resistors

Carbon composition resistors are one type among the different types of resistors that fall under the category of fixed resistor. They are manufactured using resistive elements made by mixing carbon powder with some binder and compressed into the shape of a cylinder. Small metal leads are attached to the end and the entire body is coated with some protective materials.

Such resistors are available in the range of few ohms to mega ohms. They are still extensively used in electronic devices; however, their tolerance range is often between ±5% to ±20%. Among the different types of resistors, carbon composition resistors tend to generate more electrical noise, making them less preferred for high-precision applications.

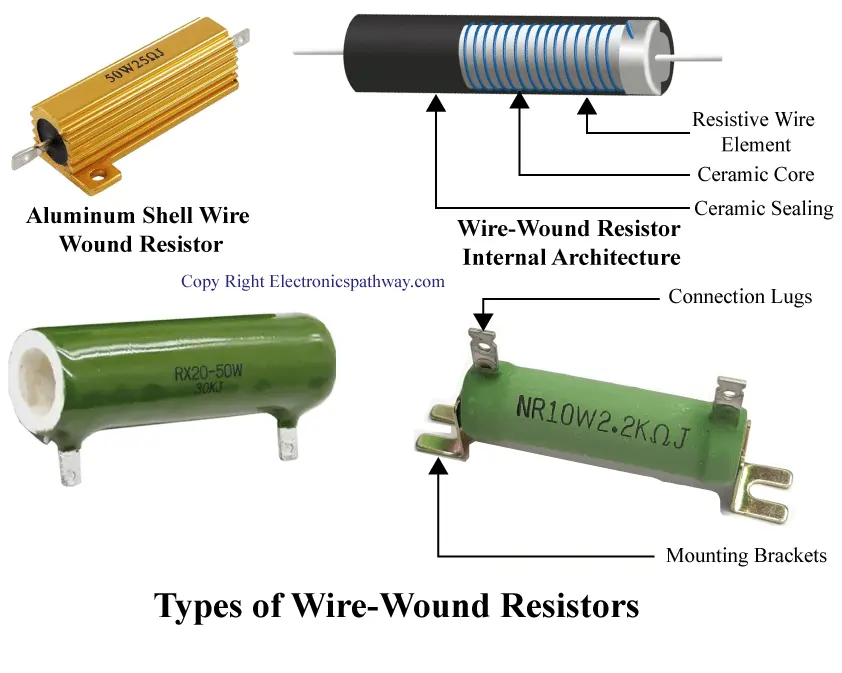

Wire Wound Resistors

Among different types of resistors, Wire wound resistors are a type of resistors made by winding a wire, typically made from an alloy of high-resistance materials around an insulating core. Such resistors have high accuracy and stability and offer excellent precision and tight tolerance levels.

These resistors generate very little electrical noise and are excellent for low-signal circuits. However, due to coil wire structure, wire wound resistors are not preferred in high-frequency applications as they may exhibit inductive behavior.

These resistors are available in the range of 2 watts up to 100 watts or more and can operate safely up to 3500C or more.

Major Application of Wire Wound Resistor

- Power Electronics

Since wire wound resistors can withstand large currents they are often used as dumb loads to dissipate large amounts of power.

- Precision Circuit

Wire wound resistors are commonly used in precision measurement devices and high-accuracy analog sensors due to their stability over a long time.

- Temperature Sensitive Devices

These types of resistors can withstand a higher range of temperatures making them useful in temperature-sensitive applications.

Thin Film Resistor

Thin film resistors are more precision resistors and are manufactured by depositing a very thin resistive material layer overlaid on insulating materials usually a ceramic substrate. This layer thickness is usually in the range of a few nanometers up to micrometers making it suitable for highly accurate resistance value.

Since a thin coating of film is deposited on the insulating substrate, they are unable to handle large amounts of power.

Major Application of Film Resistors

- Precision Circuit

Thin film resistors are extensively used in medical devices and high-precision measurement equipment due to their high accuracy and stability.

- High-Frequency Application

Unlike wire wound resistors these resistors do not exhibit inductive behavior and due to low noise and stable performance they are preferred in high-frequency applications. They are often used in Radio Frequency circuits and communication devices.

Based on the composition nature these thin film resistors are further divided into two types

- Carbon Film Resistor

- Metal Film Resistor

Carbon Film Resistor

Among different types of resistors, the carbon film resistors are manufactured by depositing a thin layer of carbon on an insulated substrate. This kind of resistors is widely used in electronic circuits as they have tighter tolerance, and are more stable as compared to carbon resistors.

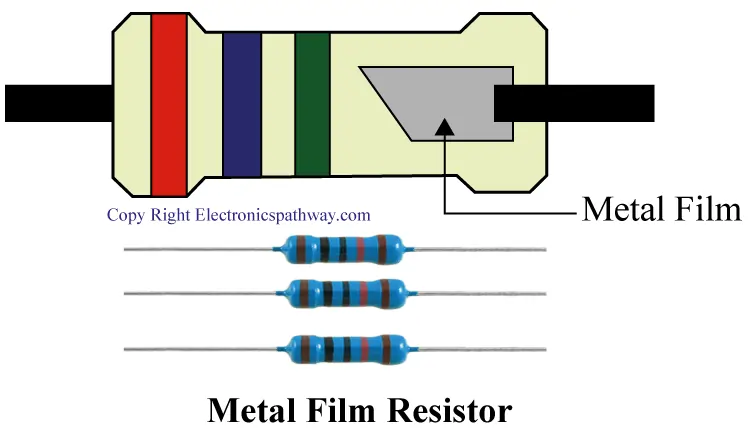

Metal Film Resistors

The only difference between the carbon film and metal film resistor is the film coating. In a metal film resistor instead of carbon film a thin metallic substrate is coated on the insulating material to form a metal film resistor.

Metal film resistors are tiny, cheap, and reliable in operation. Compared to carbon film resistors metal film resistors offer several advantages: tighter tolerances, less sensitivity to temperature change, and lower noise.

Thick Metal Film Resistors

Thick metal Film resistors are another variation of metal film resistors designed with a thicker layer of resistive metal material. Unlike thin film resistors, the deposition layer in thick metal film resistors is significantly thicker. This thicker deposition layer provides several advantages viz durability, high power handling, and stable performance.

Thick Film resistors are further divided into the following types:

- Metal Oxide Resistors

- Cermet Film Resistors

- Fusible Resistors

Metal Oxide Resistors

Metal Oxide Resistors are manufactured by depositing a thick film of the Tin Chloride layer on a ceramic substrate. These resistors are available in a wide range and are known for their high-temperature stability, reliability, and high power compared to carbon-based resistors.

Cermet Oxide Resistors (Network Resistors)

The word Cer-Met comes from two words Cermic and Resistor. This resistors are made from the composition of metal and ceramic. This composition of metal and ceramic provides the advantage: of high-temperature resistance and gradual wear of resistance. In such resistors multiple resistors are integrated into a single package, making it more compact. This saves space and makes it easier for fabrication in printed circuit boards.

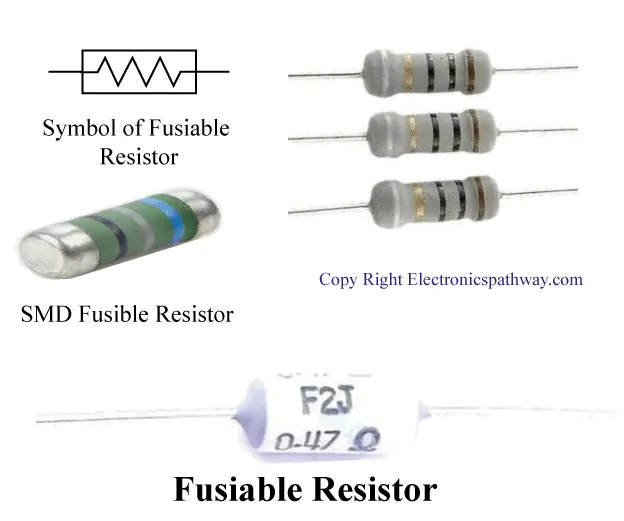

Fusible Resistors

Fusible resistors are almost similar to wire wound resistors, however, they come with a built-in fuse, hence the name fusible resistors. They are designed to operate similarly to the conventional resistor however, when the current flows above the power rating then the resistor is fused, i.e. it breaks the flow of current. This property makes them usable in overload protection.

They are widely used in power supplies, consumer electronics, and other expensive electronic circuits to protect against overcurrent or short-circuit situations. Such resistors generally have low ohmic values of less than 10 ohms.

Variable Resistors

As the name indicates, variable resistors are among different types of resistors whose resistance value can be adjusted over a defined range. Most variable resistors have a movable dial, knob, or screw to manually adjust the required range. They consist of a fixed resistive element and a sliding contact (or wiper) that moves across the resistive material.

This design typically results in three terminals: one connected to the sliding arm and the other two to the fixed resistor. When all three terminals are used, the device functions as a variable resistor. Among the different types of resistors, these resistors are commonly used where it is necessary to adjust the resistance dynamically to control parameters like voltage current or signal.

This adjustability makes variable resistors useful in various applications, such as volume controls, light dimmer circuits, and sensor calibrations.

Working Principle of Variable Resistors

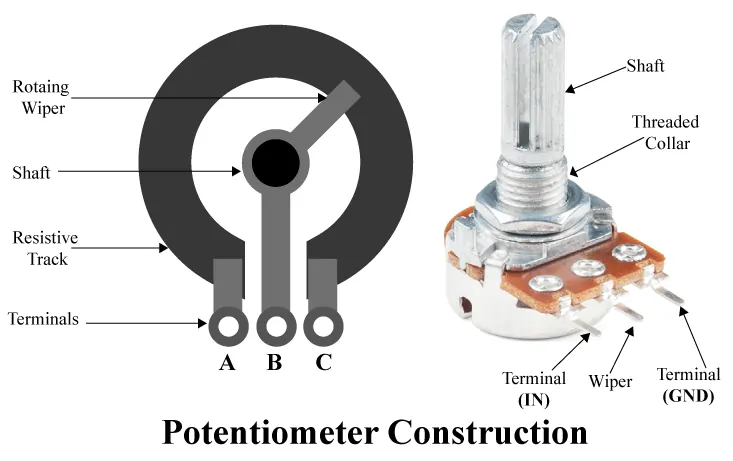

Although there are various types of variable resistors, their working mechanism remains fundamentally the same. When closely examined, variable resistors have a fixed resistance between terminals 1 and 3, known as the resistor track. The third terminal (terminal 2) is connected to a knob that has a wiper attached to it. This wiper moves freely across the resistive track as the knob is adjusted.

By changing the position of the knob, the wiper shifts along the resistive element, effectively dividing the track into two parts. This movement alters the resistance between terminal 2 and the other two terminals (1 and 3). As the wiper moves closer to one end of the track, the resistance between the wiper and that terminal decreases, while the resistance to the other terminal increases. In this way, adjusting the knob allows for different resistance values to be achieved within the circuit, providing precise control over the flow of current or voltage.

This simple yet effective mechanism makes variable resistors ideal for applications such as volume control, LCD brightness control, and sensor calibration where real-time adjustments are necessary.

Variable Resistors are further divided into the following major types:

- Potentiometers

- Rheostats

- Trimmers

Potentiometers

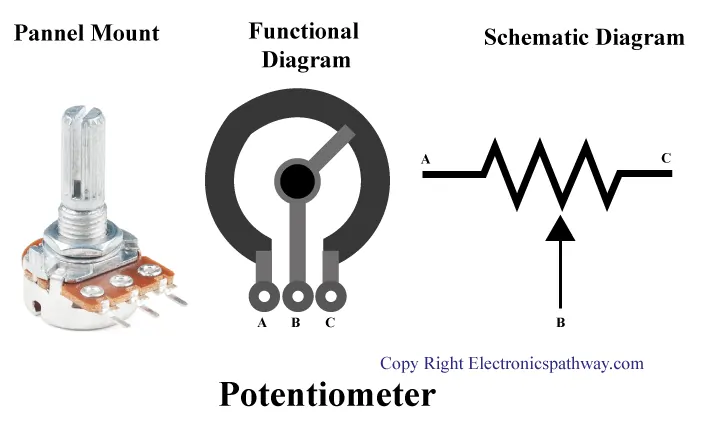

Potentiometers are three-terminal variable resistors commonly used for adjusting voltage levels within a circuit. They work by varying the resistance between two points along a resistive element, thereby allowing the creation of an adjustable voltage output.

Fixed Resistance: The resistance between the two terminals (Terminals 1 and 3) remains constant and acts like a fixed resistor.

Variable Resistance: The third terminal(Terminal 2), often attached with knob moves along the fixed resistive track (formed by terminals 1 and 2). By rotating this knob we can adjust resistance and output voltage.

This way, Potentiometers can be used as a voltage divider and these resistors are called variable composition resistors. They are available for up to 10 Mega Ohms. However, due to mechanical movement, the wiper can wear out, leading to degradation in performance.

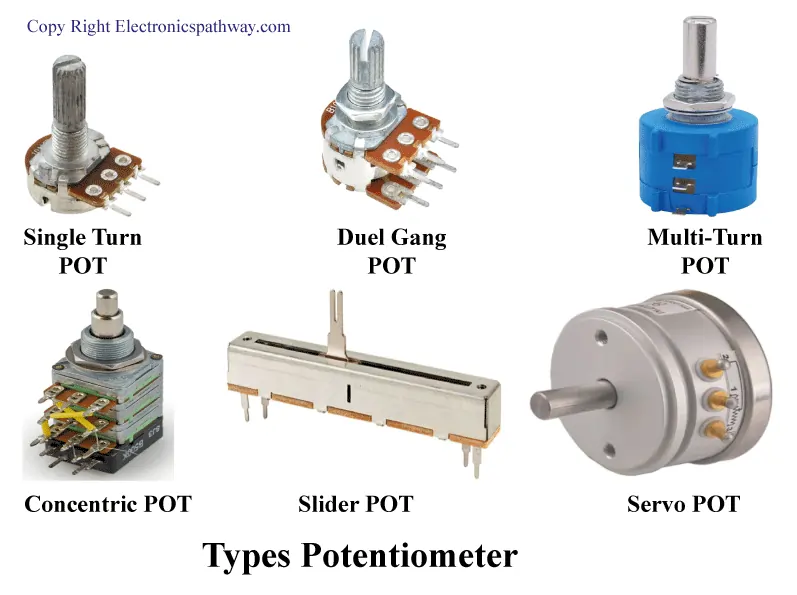

Such manually adjustable Potentiometers are further divided into two broad types:

- Rotatory Potentiometers

- Linear Potentiometers

Rheostats

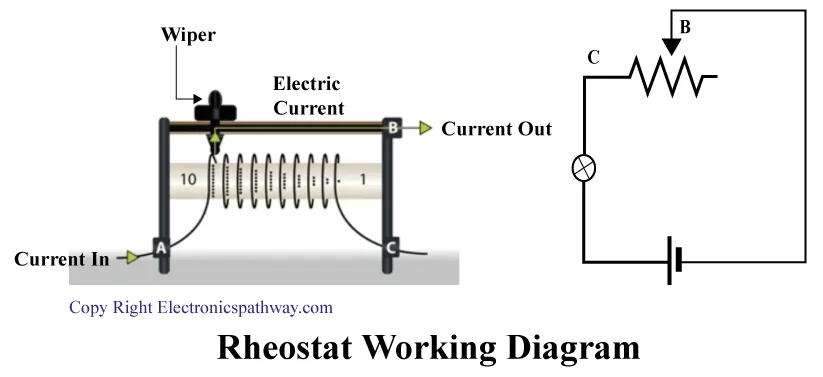

A rheostat is a type of variable resistor, which can have two or three terminals similar to potentiometers but are specially designed to control current. Unlike potentiometers which are used for voltage control, rheostats are extensively used to control the flow of current.

They are used for applications like motor speed control, heater regulation, and light dimmer circuits. Rheostats are also known as tapped resistors or variable wire wound resistors. Rheostats work similarly to the potentiometer but alter the effective resistance with the help of a wiper.

When the wiper moves closer to the start of the track this decreases the resistance allowing more current to flow. Similarly, moving the wiper further along the track increases the resistance hence reducing the flow of current.

So, what is the main difference between a Potentiometer and a Rheostat then?

Although there are different types of resistors, the major types of variable resistors are potentiometer and rheostats. The potentiometer and rheostats are similar in all respects however, the main difference between them lies in their function, configuration, and typical application. The potentiometer is primarily used to adjust voltage while the rheostat is focused on regulating current flow.

| Key Features | Potentiometers | Rheostats |

| Primary Use | Voltage Control(acts as a voltage divider) | Current Control(varies resistance across the track) |

| Number of Terminals | They have three terminals (two fixed and one wiper) | Mostly, they have two terminals sometimes three. |

| Major Application | Extensively used in lower power circuits (e.g. Audio Control, Brightness control of Display). | Extensively used for High-power circuits ( Speed control of motors, Light dimmer circuits) |

| Principle of Operation | Adjust voltage by dividing the resistive track. | Adjust the current by varying the length of the resistive wire. |

| Common Use | Volume control and Sensor calibration | Motor Speed control and heater regulation. |

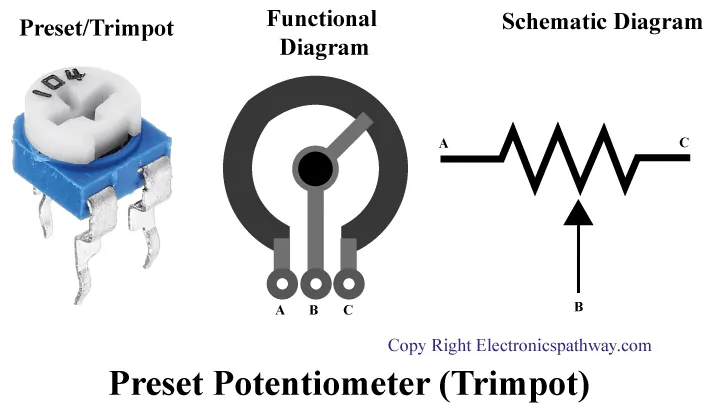

Trimpot or Trimmers

A Trimpot or trimmer is a small potentiometer that is specially used for fine-tuning or calibration in the circuit. They are also known as preset resistors and are often set once during initial setup and are only adjusted by experts or for fine adjustment in the circuit.

Normally trimmers can be adjusted using a screwdriver. They can be of single-turn or multi-turn types. Single-turn is used in cases where a resolution of one turn is sufficient, however, when extreme fine-tuning is necessary multi-turn trimmers are preferred.

Non-Linear Resistors

Till now, among the different types of resistors, we have covered linear resistors. Now, lets talk about Non-linear resistors.

Non-linear resistors are types of resistors whose value does not remain constant but varies with changes in voltage, current, temperature, or other environmental conditions. Unlike linear resistors, non-linear resistors do not follow Ohm’s law and exhibit a more complex relationship between current and voltage. There are many types of Non-linear resistors however most common types are :

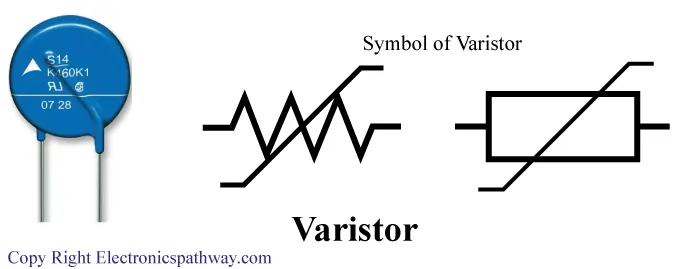

- Varistor (Voltage Dependent Resistors, VDR)

- Thermistor

- Light Dependent Resistor (LDR)

Varistors (VDR)

As the name implies Varistor is composed of two words: variable and resistors – so varistors are a type of voltage-dependent resistors. Resistance of the varistor decreases with the increase in voltage. In case of excessive voltage, the resistance drops drastically. This behavior makes them most suitable for surge protection and voltage clamping in power supplies.

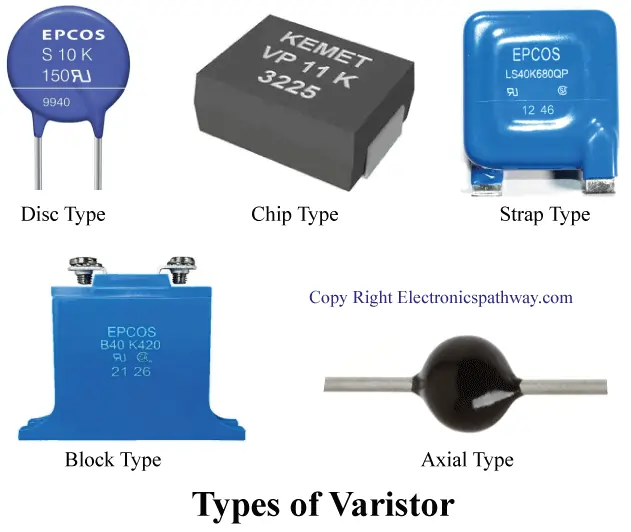

The most common types of Varistors are

- Metal Oxide Varistor

- Silicon Carbide Varistor

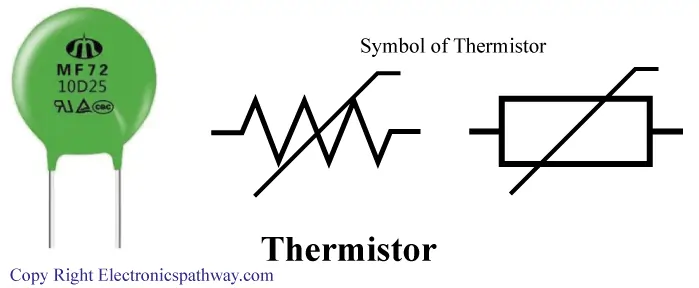

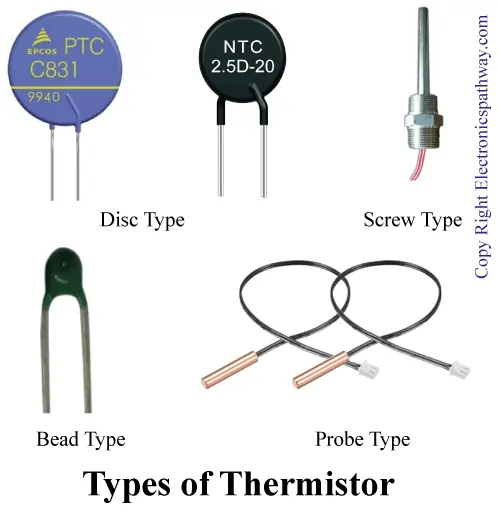

Thermistors

Thermistors are a special type of resistors whose resistance changes significantly with temperature variations. The word thermistor is composed of two words “thermal” and “resistors”.

So, in simple language, we can define a thermistor as a type of resistor whose resistance value is directly influenced by the temperature. Thermistors are further of two types:

- PTC (Positive Temperature Coefficient) Thermistors

- NTC (Negative Temperature Coefficient)Thermistors

PTC thermistors have a positive temperature coefficient which means their resistance increases non-linearly with the temperature rise, however, NTC thermistors have a negative temperature coefficient which means their resistance decreases non-linearly with the temperature rise.

Major Application of Thermistors

Temperature Monitoring

Thermistors are extensively used in digital thermometers or temperature-measuring devices as they are sensitive to changes in temperature.

Fire Alarm

Since the resistance of the thermistors is influenced by the change in temperature, this feature of the thermistor can be utilized in developing Fire Alarm circuits.

Over Current Protection

When the current exceeds a certain limit through an electronic circuit or devices, it generates heat. The thermistor can be used to detect such overcurrent and can be used as protection in the circuit to prevent over-exceeding of the current.

Temperature Control

These thermistors can be used to control the heating element to maintain preset temperature and when it exceeds the set limit it breaks the supply to re-establish the original preset temperature.

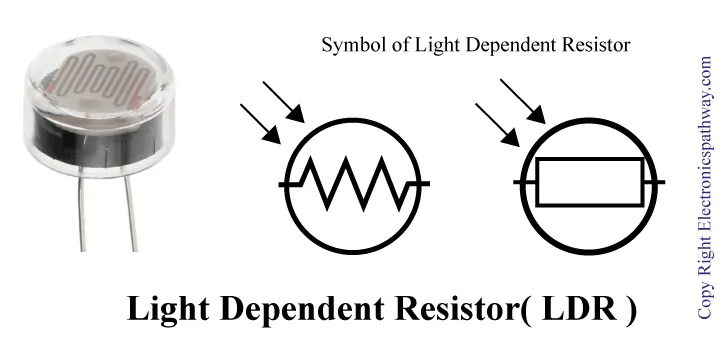

Photo Resistor or LDR (Light Dependent Resistors)

Photo Resistors are also known as Light Dependent Resistors(LDR). As the name suggests, these types of resistors are responsive to the intensity of light. As light intensity increases, the resistance of such resistors decreases, and as light intensity decreases the resistance of such resistors increases in a non-linear fashion. In simple words, they show a negative correlation with the light intensity.

Major Application of LDR

Automatic Lighting Systems.

LDRs are responsive to the intensity of light. This feature of LDR can be used to develop an automatic street lighting system. The lamp will glow as soon as the intensity of the light decreases and switch off when the intensity of light increases.

Brightness Control

They are also used in different gadgets to automatically adjust the brightness of the display according to the surroundings.

Solar Tracking

LDRs are also used in devices that need to track the position of the sun and are frequently used in devices for such applications.

Important Parameters of Resistors

We have gathered a lot of information about types of resistors, now let’s see some of the important parameters of resistors before going into summary guidelines on the selection of resistors.

It is always the best approach to refer datasheet of resistors before choosing resistors for a particular application. However, for general applications, it is essential to look for some of the essential key parameters to ensure compatibility and performance. Some of the most important parameters of resistors are:

Resistance Value(Ohm, Ω)

- This is the most basic and critical parameters, and it is measured in Ohms.

- It signifies how much the resistor opposes the flow of current.

Power Rating(Watts, W)

- This is the second most important parameter to consider while looking for a resistor. It signifies the maximum amount of power the resistor can dissipate without being damaged.

- It is measured in Watt. The mathematical formula for Power rating . It is always recommended to choose a power rating slightly higher than the calculated value(within in range of +20%) but not too big.

Tolerance(%)

- Tolerance gives the deviation range of a resistor from its nominal value and is expressed in percentage (%).

- For example, if the nominal resistance of a resistor is 100 Ω with a tolerance of 5%, the resistor can have an actual resistance value somewhere between 95 Ω till 105 Ω.

Maximum Working Voltage (V)

- This is the maximum voltage resistor that can withstand across its leads without breaking it down or being burnt out.

- Always ensure voltage applied across the leads of a resistor is rated below its maximum working voltage.

Operating Temperature Range (°C)

- This is the temperature range where the resistor value is not much influenced due to temperature changes.

- Check for an operating temperature range of resistors if used in extreme temperatures for long-term stability and proper function.

How to Choose the Right Resistor among Different Types of Resistors.

Choosing the right resistor for a particular task can be challenging. Since there are different types of resistors each with diverse construction materials and characterstics. Several factors need to be considered while choosing the right resistor for a particular project. Here, is a general guideline on how to choose the right resistor among the different types of resistors for a particular project.

1. Selecting Resistors Based on Application Requirements

- Use a fixed resistor when you need constant resistance.

- Use Variable resistors (like potentiometer, or Trimmer) when you need adjustable resistance, like volume control, or calibrating circuits.

- Use Variable resistors like Rheostat when you need to control the current, like motor speed control, and light dimmer circuits.

2. Proper Resistance Value

- Choose a resistor based on the desired value that is closest to the ohmic value given by ohms law(V=IR).

- Usually, Resistors are manufactured in standardized value(i.e. E-Series). Use the resistor in proper combination i.e. in series or parallel to achieve the closest value.

- Check whether precision and tolerance of the resistance value are very crucial or not. For high-precision applications, choose a resistor with a tight tolerance range i.e. in the range of (±0.1% to ±1%).

- For general-purpose applications resistors with high tolerance (±5%, ±10%) can be used.

3. Power Requirement

- Choose low-power resistors of ¼ watt or ½ watt for small-power applications like signal processing or biasing transistors.

- Choose high-power rating resistors for high-power applications. Prefer to use Wire wound resistors that are designed to handle several watts for applications like motor drivers or power supply units.

4. Tolerant to Temperature

- Use metal film and metal oxide resistors if temperature fluctuation is an issue in the design.

5. Tolerate to High Frequency

- Prefer to use Carbon Film and metal film resistors when you are working with high-frequency signals like RF circuits or oscillators.

- Refrain using wire wound resistors in high-frequency applications like RF design, oscillators, etc.

6. Environmental Factors

- Prefer resistors like metal oxide or ceramic-based if circuits need to withstand harsh and high temperatures.

7. Size and Mounting

- Prefer to use SMD resistors if circuit design needs to be shrunk into small size. Such circuits are designed taking into consideration the size and portability.

- Prefer to use through-hole resistors where mechanical strength is a major factor and a large power handle is necessary.

Guideline Table to Choose Different Types of Resistors

| Resistor Type | Best Use for | Power Handling Range | Frequency Response | Precision | Temperature Stability |

| Carbon Composition | General, low-cost, low-precision applications | Low to medium | Low | Low | Poor |

| Metal Film | Precision circuits, low noise | Low to medium | High | High (±0.1% to ±1%) | Good |

| Thin Film | High-precision, high-frequency applications | Low | High | Very High (±0.05% to ±1%) | Very Good |

| Wire-Wound | High power, low resistance, inductive circuits | High (up to several watts) | Low | Low (±5%) | Excellent (Very Stable) |

| Metal Oxide | High temperature, power electronics | Medium to high | Low | Medium (±1% to ±5%) | Very Good (heat resistant) |

| Thermistors (NTC/PTC) | Temperature sensing, thermal protection | Medium | N/A | N/A | Varies (NTC/PTC) |

| LDR | Light-sensitive applications | Low | Low | N/A | Poor |

| Varistor (VDR) | Surge protection | Medium to high | N/A | N/A | Good |

| Fusible Resistors | Overcurrent protection | Medium to high | Low | Medium (±5%) | Good |

Conclusion

Since, we have studied about different types of resistors, there arrises great confusion on how to choose perfect resistors among different types of resistors. In this article we have discussed about different types of resistors their manufacturing process and uses. From fixed resistors like carbon composition and metal film resistors as well as variable resistors like potentiometers and presets. We have studied about different types of resistors which operates in linear and non-linear fashion.

In addition, we have also studied about non-linear resistors like LDR, Thermistor, and Varistor. There are different factors that need to be taken in to consideration while making a proper choice among different types of resistors. We have studied all of them in detail and also listed a table for quick reference. By considering all these factors like resistance value, its typical use and application purpose we can ensure optimal choice among different types of resistors and ensure that the performance and realibility of our circuit is meet.